Equipped with thermal management capabilities, this will improve the cooling efficiency of data centers or server rooms

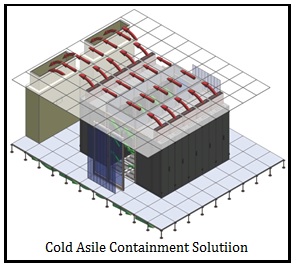

NetRack, a leading solutions provider for data centers and end-to- end IT server racks, today announced that is has enhanced its NRS-e Series product portfolio by adding a new solution ‘Cold Aisle Containment’. NRS-e series are ultra-rigid enhanced racks for high density applications running in data centers and server rooms. Applications running on servers and other equipment tend to generate a lot of heat when the equipments are housed in racks. Cold aisle containment solutions equipped with thermal management capabilities, can handle the large heat generated by IT equipments and servers, improve the air flow and prevent the mixing of cool and hot air.

end IT server racks, today announced that is has enhanced its NRS-e Series product portfolio by adding a new solution ‘Cold Aisle Containment’. NRS-e series are ultra-rigid enhanced racks for high density applications running in data centers and server rooms. Applications running on servers and other equipment tend to generate a lot of heat when the equipments are housed in racks. Cold aisle containment solutions equipped with thermal management capabilities, can handle the large heat generated by IT equipments and servers, improve the air flow and prevent the mixing of cool and hot air.

Mr Ravi Raj, Brand Head, Director Sales & Support at NetRack said, “Cold aisle containment will help improve the cooling efficiency of data center or server room by reducing cold air losses/ blocking the cold air movement to an unwanted area. In addition, they would help utilize the rack space more efficiently without increasing the PAC capacity. This can benefit DC as it leads to saving of cooling cost, energy cost and IT space.”

Features:

Thermal management with air seal kit and blanking panels and

Bottom brushed access

Grounding and bonding

Roof blowers with adjustable chimney

Back door blowers

NetRack offers NRS-e Series, a world class product which is modular  and scalable in nature and comes with an ability to accept change of layout design and reuse when incorporated with conventional CAC solutions. Cold Aisle Containment solution has standard parts like doors, top panels, vertical panels and filler panel which can ease the commission and decommission as per customer requirement.

and scalable in nature and comes with an ability to accept change of layout design and reuse when incorporated with conventional CAC solutions. Cold Aisle Containment solution has standard parts like doors, top panels, vertical panels and filler panel which can ease the commission and decommission as per customer requirement.

Cold aisle containment method will address issues like high heat densities by offering data centers and industries the finest conventional cooling with improved cooling efficiency. Cold air enters the machine critical equipment from front perforated door, pass over and cool the equipments. Hot air moves to hot aisle through perforated dual door or enter false ceiling chimney and then to PAC. Basically, it enhances cooling by creating uniformity in the aisles. It can provide numerous additional benefits like cost saving, improving PUE, emissions of lower carbon from industries and extend the life of IT equipments.